The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Ohlson Brand Check Weighers

Maintaining consistent weights is a critical aspect in any food automation process. Ohlson Brand check weighers integrate into the process to verify the end product of the production process is accurate. Regarding applications, these systems can do more than just ensure the accurate target weight of a product or packaged item. In fact, these systems can detect missing pieces of a kit, count packs, provide total shipment weights and work with a controller computer to create barcodes, shipping labels and so on.

Are you interested in this product?

We are here to help.

Features

- Ensure target weights are met to meet Department of Agriculture Weights and Measure standards or other requirements

- Reject mechanisms (Available option)

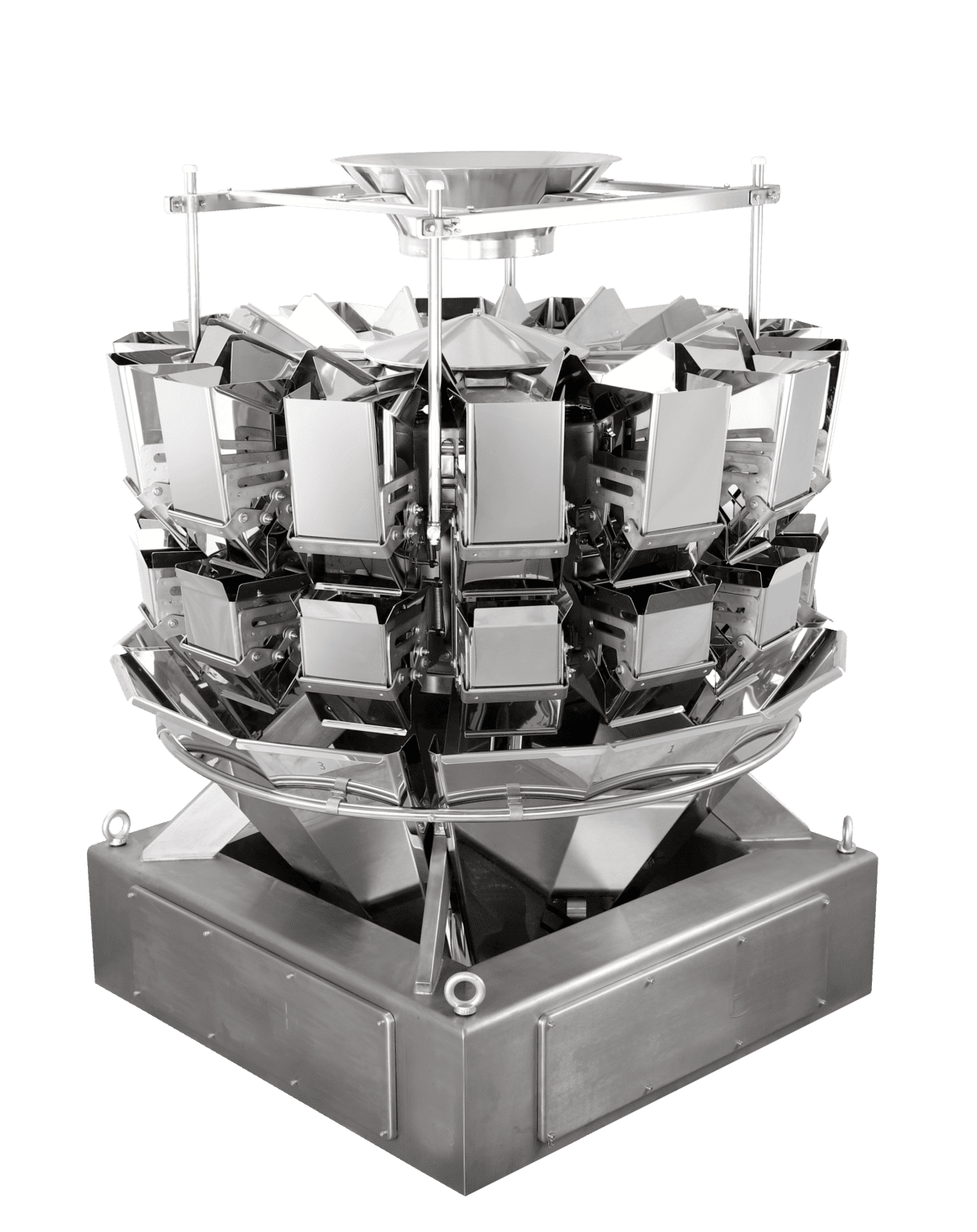

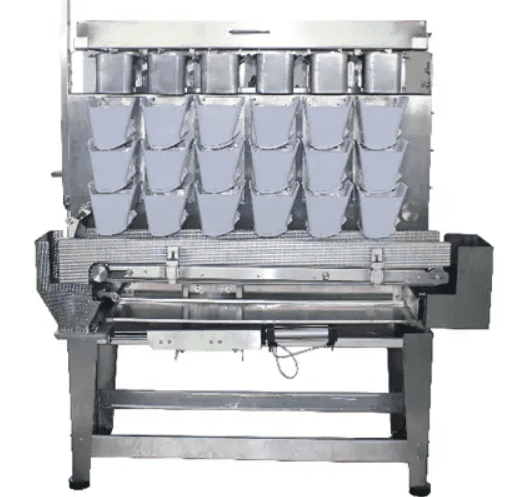

- Integrates with linear/multi-head weighers, baggers, and other systems

- Mechanical or blower reject mechanisms

- Adjustable speed belts

Standard Specs

Standard Specs

Accuracy

To 0.3 grams

Speed

- Up to 150 weighments per minute

- Linear speeds of up to 65 feet per minute

Weights

3-1000g

Belt Width

8.6″

Length of Weighing Belt

9.8″-17.7″

Accessories

Accessories

- Combination metal detector & check weigher